PROMATION USA - a world class supplier of capital equipment for micro-electronics manufacturers - has recently launched a "Soldering Technology Initiative" campaign designed to educate industry professionals about the latest technology being introduced into the world of soldering.

PROMATION has taken aim on electronics manufacturers in all industry sectors; to educate individuals and companies on the latest and greatest technologies taking place in the manufacturing industry.

To compliment a few of PROMATION USA's more recent accomplishments such as, the introduction of a new solder tip pressuring monitoring solution available on select robotic soldering systems, heated Nitrogen Kits for Lead-Free Soldering, and much more - PROMATION USA has looked to get companies and individuals (not yet ready to take the plunge into automatic or robotic soldering) to turn their attention towards technologies being used in these automated systems - now becoming available in the manual soldering marketplace.

One of the more recent services available through PROMATION USA, allows customers interested in improving their manual soldering process to take part in a complimentary service that allows companies or individuals to submit solder spools to PROMATION's PROlab for a "perforation service".

"The complimentary Solder Spool Perforation Service" - Mike Goldberg of PROMATION USA states, "gets people thinking about the applicability of these technologies in their common everyday practices".

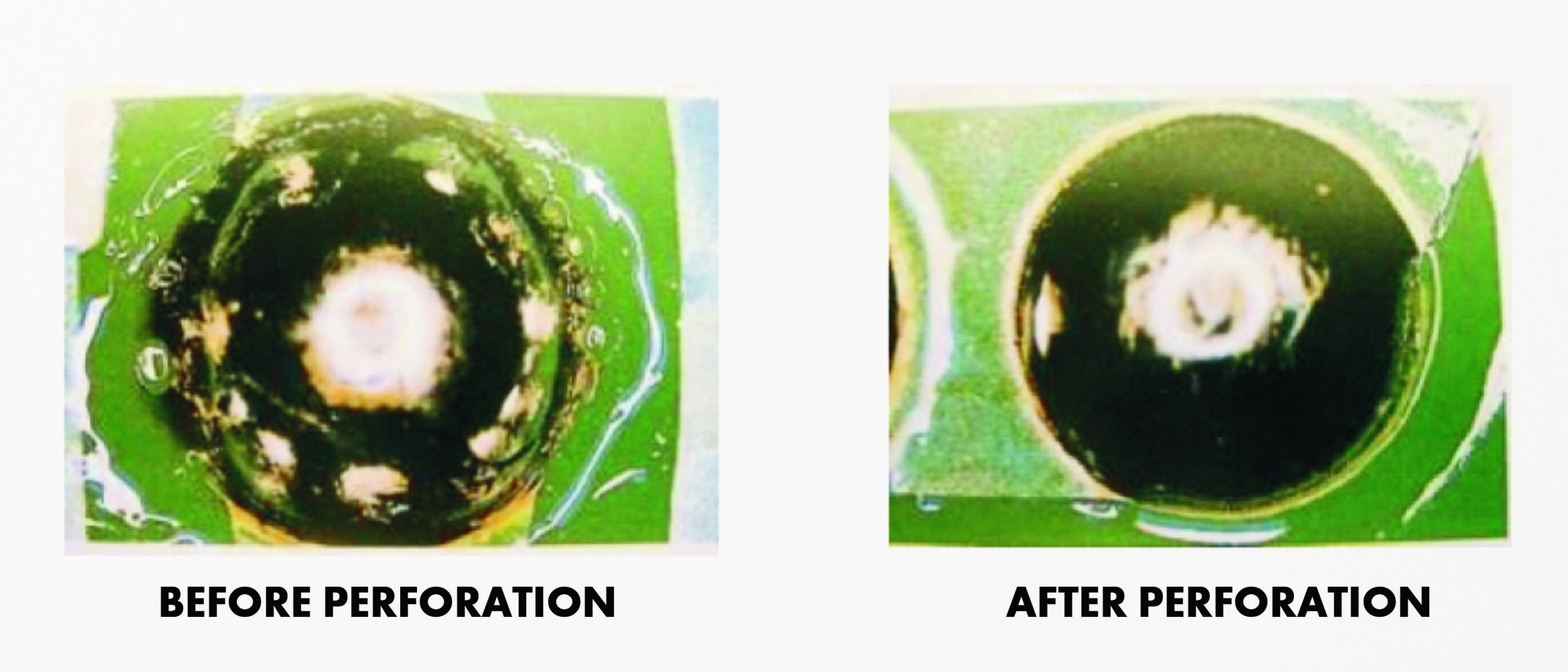

The concept behind solder wire perforation is to perforate or score the flux-cored solder wire to allow for an improved out-gassing of the inner flux core.

During the soldering process, the flux that has been extruded into the core of the solder wire, performs a specific task of removing oxidation on solder pads and solder leads to prepare the parental substrates for the formation of an inter-metallic bond. Flux, however, is flammable and secretes gasses during this process that can lead to a multitude of different results or faults such as: Solder Joint Pin-holes, Solder Ball Defects, Flux Splatter, and non-activated flux being left on the solder joint.

"The driving theory behind peripheral perforation devices is that they allow the gasses created during the solder process to escape more efficiently reducing defects and allow for an improved bond to take form," continues Mike Goldberg. "The fact that companies and individuals are turned-off from exploring these technologies due to the perceived notion that they are only available on robotic solutions is a serious mistake. Many of our current customers and solder wire suppliers have provided incredible data and feedback on the performance of these types of solutions and we are delighted to now have the opportunity to present these technologies at an affordable and easily attainable price."

Complimentary services like these are designed to open the eyes of industry professionals and remind everyone that there are a plethora of emerging technologies that offer solutions to common well-known industry problems.

"Perforation technology is well on its way to becoming a common technology practice among electronics manufacturers; as its benefits are easily seen and documented during lab testing and real world applications," concludes Mike Goldberg.

PROMATION USA features a full line of perforation technology products - not just on the robotic soldering side - but also on the manual/ hand soldering spectrum.

Perforation Products Include: The QUICK 300 Series Perforation and Respool Station, the QUICK 376DI Semi-Automatic Soldering Station, QUICK 372B Table-Top Perforation Solder Feed Station, and many more.

For more information on solder wire perforation technologies and application specific inquires, please contact PROMATION USA direct at: 1.262.764.4832