system Specifications:

Three Axis Robotic Soldering Station

Z Axis = 100mm Stroke

X Axis = 100mm Working Area

Y Axis = 100mm Working Area

150 Watt Power Supply

High Precision Automatic Solder Feeding Station

Teaching Method = 9011D Teaching Pendant (Point & Teach)

USB Program Back-up

Positive Solder Tip Location (Cartridge Style)

50-500°C Programmable Temperature Control

Simple and Easy To Use Program Interface

Ideal for In-Line Application or Custom Integrations

9153A SERIES Soldering Robot

Call for pricing

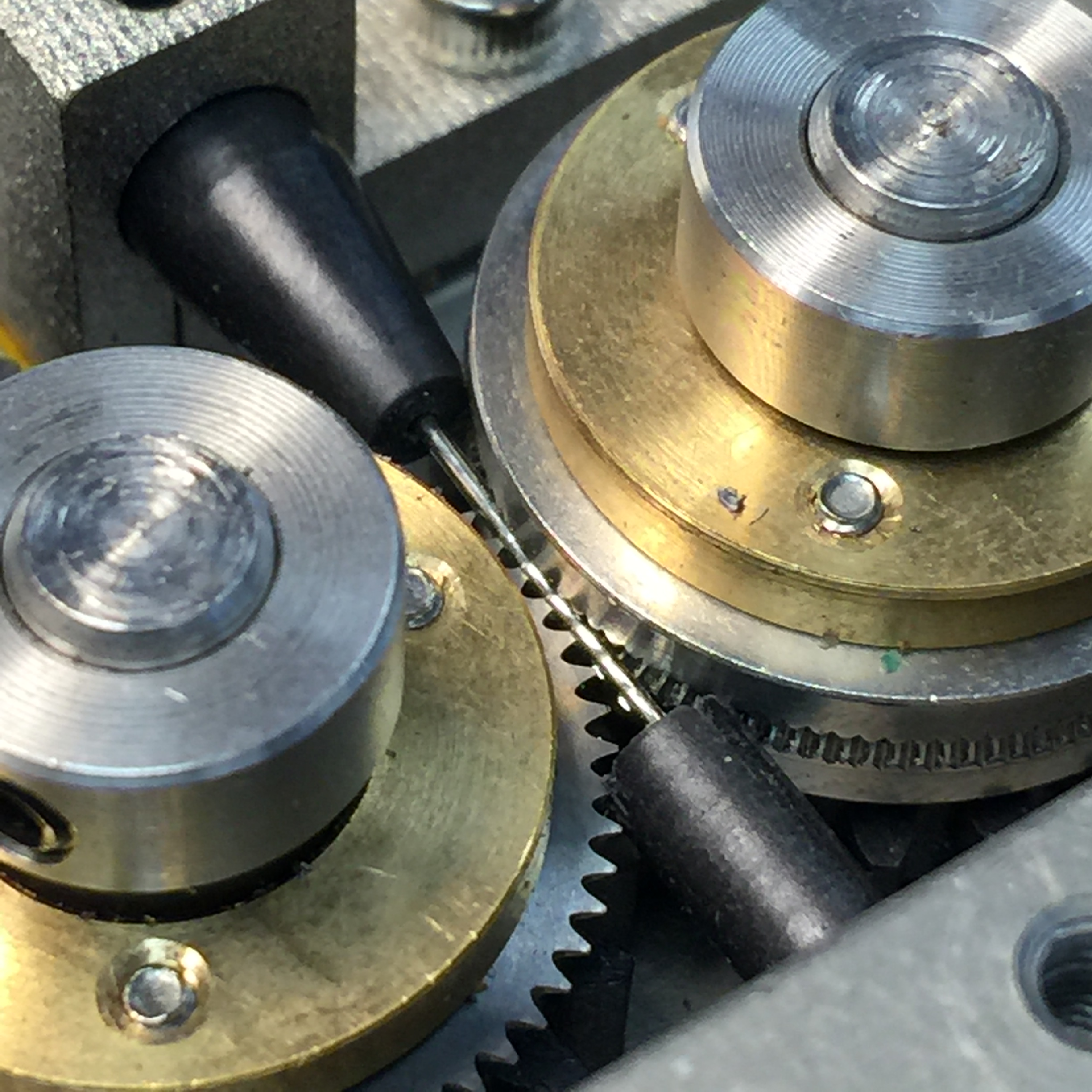

The QUICK 9153A series of Soldering Robots feature a robust Hot Iron system with a superior closed loop temperature sensor. The Hot Iron is capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. Two fine-toothed gears work to pull Solder from the Solder Spool while also perforating the surface of the Solder Wire to allow for better out gassing of the Flux Core. Better out gassing results in less solder ball and flux splatter.

All systems come standard with a 150W Power Supply capable of maintaining a tip temperature of up to 500°C, automatic solder feeder, tip cleaning station, and positive tip location. Nitrogen blanket sleeves, vision guidance, Color CCD "Witness Cameras" and light screen safety enclosures are all available options.

Options:

- Safety Enclosure

- Heated N2 Soldering Kit (Ideal for Lead-Free Applications)

- Upgraded Solder Tip Cleaning Stations

- HD Process Viewing Camera Kit

- Dynamic Vision Alignment Camera Kit

- 9036 Solder Tip Correction Device

- Additional I/O (For Custom Integrations)