9494F Table-Top Soldering Robot

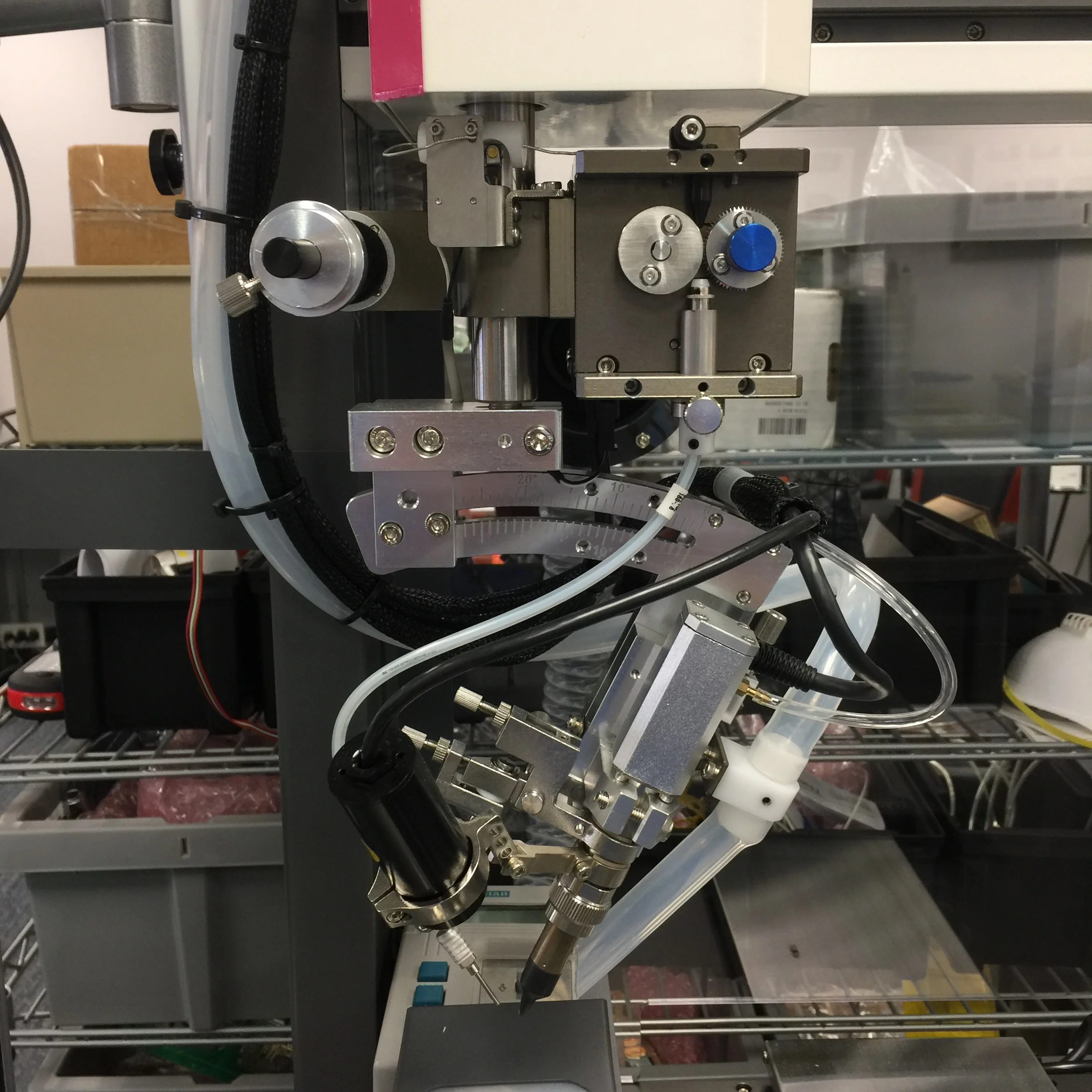

The 9494F Table-Top Soldering Robot features a robust Hot Iron system with a superior closed loop temperature sensor capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. Complete with a 150W Power Supply, a Wire Perforating Solder Feeder, 4-Axis Motion, Extended 50mm "Z-Axis" Clearance, Adjustable End Effector, and a Tip Cleaning Station this system is more than capable of handling most any Soldering Application. The overall machine footprint size is reduced, but with the design of the gantry allowing for more work space, the machine features a more than capable 400mm x 400mm Range of Motion.

9494F Soldering Robot Offering New Technology:

The 9494F has been redesigned to offer users the latest in soldering technology. The new upgraded unit is compatible with the following new technologies:

Solder Tip Pressure Monitoring Solution

Upgraded Solder Feed Station (for applications that require a higher degree of rotation)

New Elegant Exterior Color Scheme

New Quieter Operation

SYSTEM SPECIFICATIONS

VOLTAGE: 110V AC

POWER SUPPLY: 150W

TEMPERATURE RANGE: 50°C-500°C

AXIS: 4

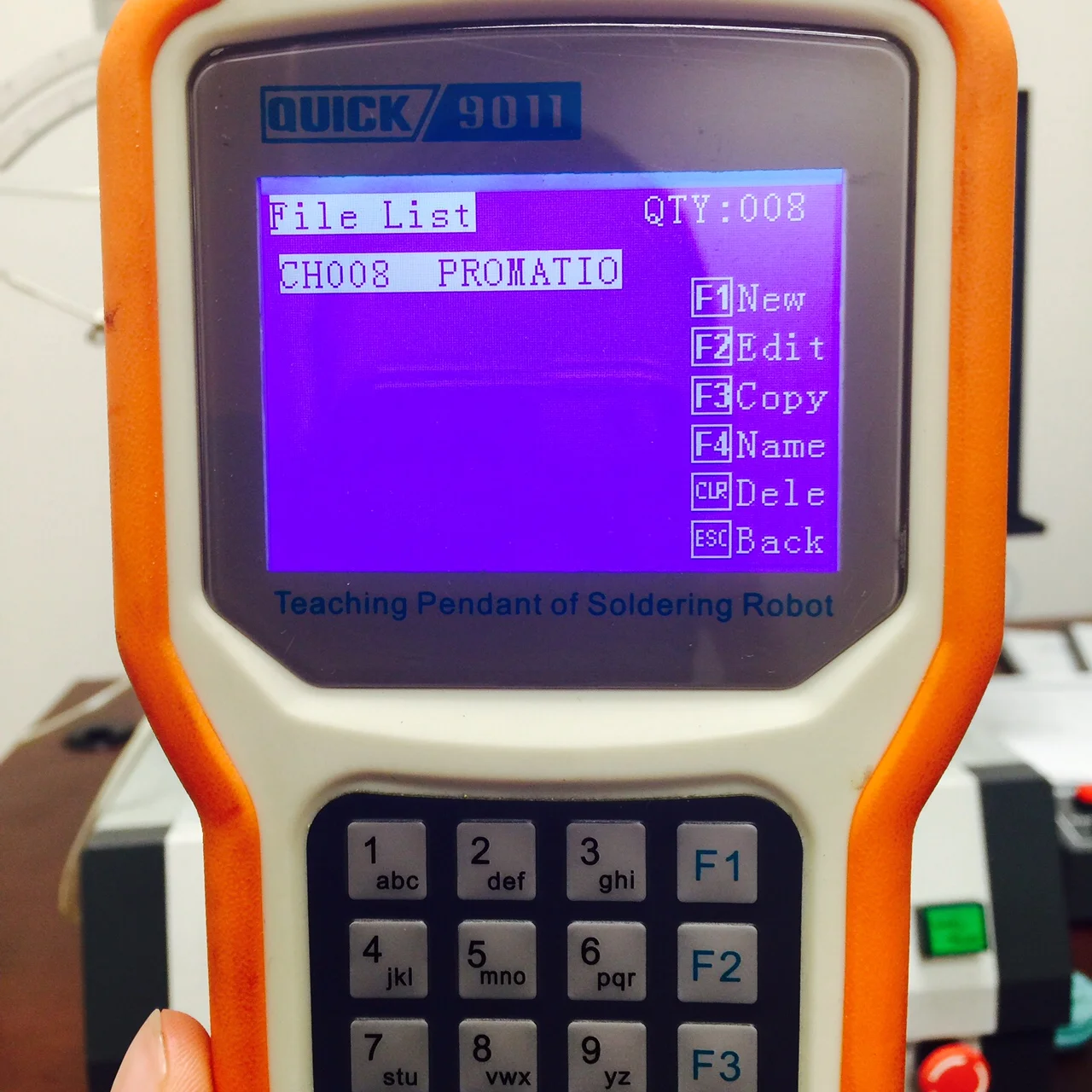

COMMAND PER PROGRAM CAPACITY: ≤999, Max, 60000 points

ON BOARD FILE STORAGE: ≤256 Programs

MACHINE SIZE WxDxH: 914x760x1066mm

WORKTABLE MAX LOAD: 11lbs

HEAD MAX LOAD: 4lbs

MOVEMENT RANGE:

X-AXIS 400mm

Y-AXIS 400mm

Z-AXIS 100mm

R-AXIS 300°

SPEED RANGE:

X-AXIS 0.1-600mm/sec

Y-AXIS 0.1-600mm/sec

Z-AXIS 0.1-200mm/sec

R-AXIS 0.1-600°

REPEAT ACCURACY:

X-AXIS ±0.02mm

Y-AXIS ±0.02mm

Z-AXIS ±0.02mm

R-AXIS ±0.02°

STEPPER RESOLUTION:

X-AXIS 0.01mm

Y-AXIS 0.01mm

Z-AXIS 0.01mm

R-AXIS 0.01°

ENVIRONMENTAL CONDITIONS:

TEMPERATURE 0-40°C

HUMIDITY 20-90%