Signature Closed Loop high frequency heating system provides rapid and stable power to the tip.

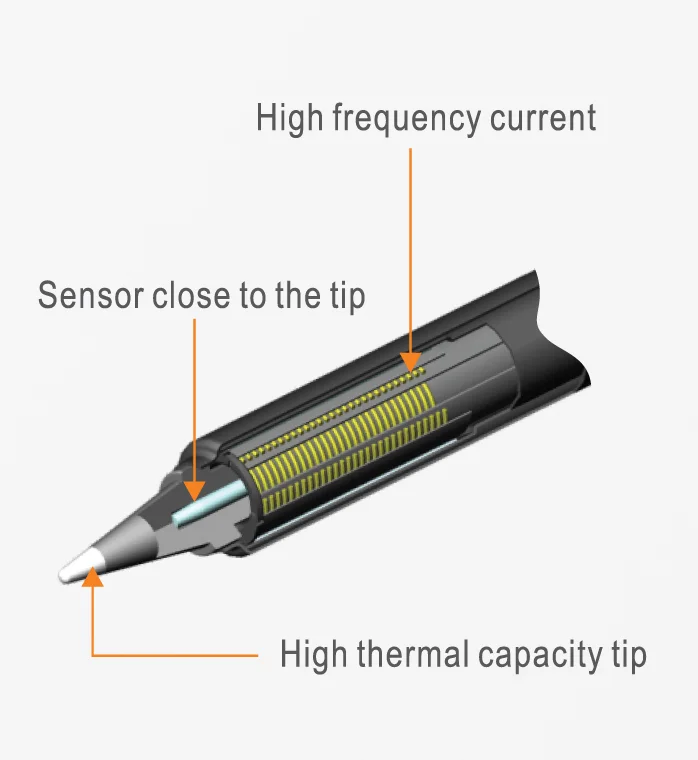

In the world of soldering, the thermal feedback loop is one of the most critical and important features on the soldering system. All soldering irons feature a real-time thermal feedback loop while offering quick and easy solder tip replacement. The thermal sensor is positioned at the end of the solder tip's contact point to provide excellent communication and accurate thermal feedback to the power supply.

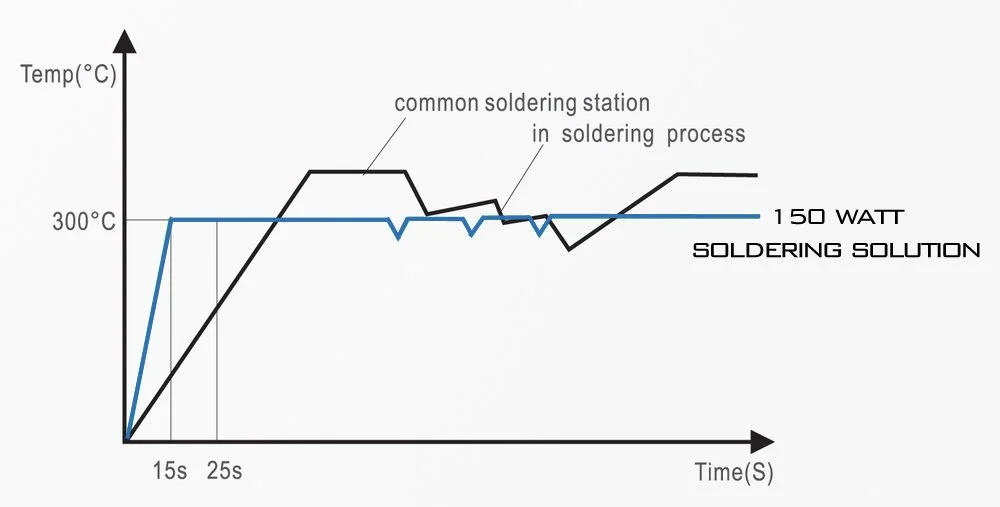

Our heating element uses a special induction coil. When this coil is flooded with high-frequency AC a magnetic field is generated. The magnetic beam travels through our magnetized rod (sensor) to generate an induction current. This current changes the density of magnetic field and generates heat. The heating current has a thermal effect that allows the tip to quickly heat and maintain temperature (as shown in the chart). The result is an “Eddy Current” that provides .excellent temperature control throughout the entire soldering process.

Power supplies and soldering irons are offered in a multitude of different wattage and styles; ranging from 90 Watt solutions - up to 320 Watt Solutions. .

Here at PROMATION USA the concept always remains the same; to provide a superior thermal feedback loop while maintaining the "lowest cost of ownership" in its class. Our expert team can assist in directing your application towards the very best heating technology and robotic solution.